Nook Industries and Design World discuss how Wear Indicator Nuts for jacks can support your application. Make Motion Work for you.

Tag Archives: ball screw life

All Your Equations In One Place

When a linear motion solution is in place & running, it’s easy for the casual observer to think it looks easy. That’s what our industry is all about; making the difficult or even impossible look easy.

But what few people outside the industry realize is just how much work needs to go into the design of a successful linear motion system. The old adage “Measure twice, cut once” doesn’t even begin to cover all the variables, that have to be dealt with.

Now, a new app looks to make that successful design at least a little easier. The Design Guide Pro not only offers selectors for Bevel Gears, Worm Gear Jacks, Bearings and Electric Cylinders, but it also has a calculator section. Here, you’ll find tools to help you establish Energy, Critical Speed, Column Load, Torque and Nut Life as well as helping with Unit Conversions.

All in the palm of your hand. Check it out today by clicking here.

#MakingMotionWork

Loading a Standard Ball Nut

Check out these videos on how to load a standard ball nut:

When the arbor will not slide over the machined journal

When the arbor will slide over the machined journal

#MakingMotionWork

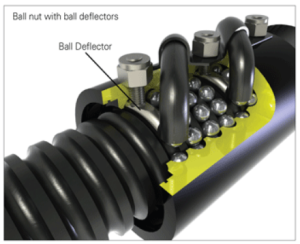

4 Reasons Why Your Ball Screw Assembly May Fail

Premature failure may be caused by any of the following:

- Misalignment of the ball nut to the screw which results in side loading or eccentric loading will reduce life. Additionally, this may cause the ball bearings to split or get flats on them. The ball bearings may even break out of the return tubes.

- Metal chips, dirt or debris in the ball nut may impede the call bearings from free circulation. The ball bearings may get flats on them because of skidding,

- Lack of lubrication. Proper lubrication will help dissipate heat and reduce metal-to-metal wear of components.

- Exceeding the ball nut critical speed can break pickup fingers off, causing the balls to come out of the nut. Exceeding the screw critical speed will cause the whip resulting in misalignment.

#MakingMotionWork

Three Popular Screw Types Defined

When considering the vast majority of applications in which machine screws are used, it’s important to review the functions of some of the major types of screws. Below, we’ll take a look at the designs, functions and more while we define acme, ball and planetary screws.

Acme Screws:

The acme screw thread, sometimes referred to as the trapezoidal thread, is used for lead screws. They are often needed for large loads, or when the environment is less than desirable.

The acme thread form has been around for over a century, replacing square thread screws which had straight-sided flanks and were difficult to manufacture.

There are two main classes of acme thread forms: general purpose (G) and centralizing (C). The general purpose and centralizing thread forms have a nominal depth of thread of 0.50 x pitch and have a 29 degree included thread angle, which has allowed companies to develop unique screw diameters and leads. European metric Trapezoidal thread forms have a 30 degree Included thread angle.

When compared to general-purpose thread forms, centralizing threads are manufactured with tighter tolerances and reduced clearance on the major diameter. For instance; If an acme nut is side loaded with a radial load, a “G” class will wedge when the nut thread flanks come in contact with the screw thread flanks. To prevent this wedging, a “C” class thread form can be used, since it utilizes less clearance and tighter tolerances are allowed between the major diameter of the nut and the major diameter of the screw.

Industry leaders have developed several unique thread forms, such as stub acme forms and 40 degree included angle, which allow them to provide a variety of diameter and lead combinations.

Ball Screws:

For loads requiring a greater amount of efficiency, companies often turn to ball screws. A ball screw assembly is a device comprised of a nut, screw, and reciprocating ball bearings. The bearings provide the thread engagement between the nut and screw.

Ball screws offer an efficient means for converting rotary motion to linear motion. A ball screw is an improvement over an acme screw just as an anti-friction ball bearing is an improvement over a plain bushing.

In the long run, ball screw systems can prove to be a cost-effective alternative to pneumatic or hydraulic systems, which require constant electrical and air power.

Planetary Roller Screws:

Planetary roller screws are remarkable devices designed to convert rotary motion into axial force or vice versa.

The planetary roller screw design offers multiple advantages and reliability for the most demanding applications when compared with other lead screw types due to its rolling motion. These screws offer high efficiency even in relatively shallow lead designs.

The multitude of contact points can carry large loads and provide very high resolution (small axial movement) when using very shallow leads. Planetary roller screws produce high rotational speeds with faster acceleration without adverse effects.