There are several factors conducive to a ball nut failing prematurely, such as misalignment, impact loading, a lack of lubrication, contamination or external damage to the return circuits. However, the primary failure mode for ball nuts is fatigue of the bearing balls or thread surface. Premature failure may result in the loss of some or all of the balls between the nut and screw. When all the balls are lost, the nut is no longer engaged with the screw and therefore may not move when the screw is rotated or, in vertical applications, will free fall along the screw.

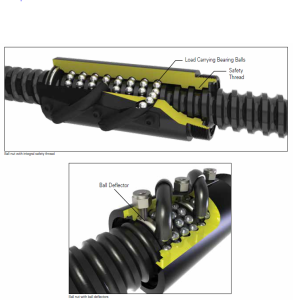

In applications where this loss of ball type failure could result in injury or death, this failure needs to be considered in the design. Possible preventative measures include the use of two or more screws supporting the load, use of nuts with multiple independent ball recirculation circuits, use of ball deflectors which prevent the balls from exiting the ball nut out the ends or use of industry-leading integral safety thread ball nuts.

The integral safety thread is a unique solution that provides the ball nut with a secondary safety thread– a reverse thread in the nut body itself. This special thread extends from the ID of the nut to below the OD of the screw without making contact. In the unlikely event that all the balls in the nut are lost, this safety thread will engage the screw and prevent free fall.

Although this thread can be used to lower the load to a safe position, it is not to be used otherwise. This can also be accomplished with the use of a special flange if the ball nut body cannot accommodate the safety thread feature.