Of all the screws in industry used for motion, ball screws provide unique benefits when compared to other standards, such as roller screws or acme screws. A ball screw is a device comprised of a shaft and a nut where either of which can be the traversing component.

Ball screws work similarly to ball bearings, where hardened steel balls move along an inclined-hardened inner and outer race. With at least 90 percent efficiency, ball screws are one of the most efficient ways of converting rotary motion into precision linear motion. When it comes to ball screws, there is some key terminology to understand.

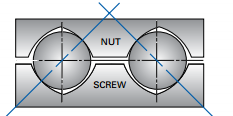

The ball circle diameter is the diameter of the circle created by the center of the ball bearings when they come into contact with both the screw and nut. The root diameter is the minimum diameter of the screw measured at the bottommost point of the threads. Both diameters are important when calculating application characteristics and sizing parameters for factors such as column loading and critical speed.

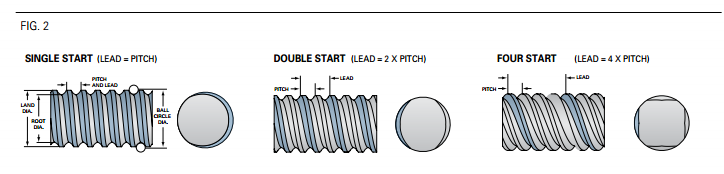

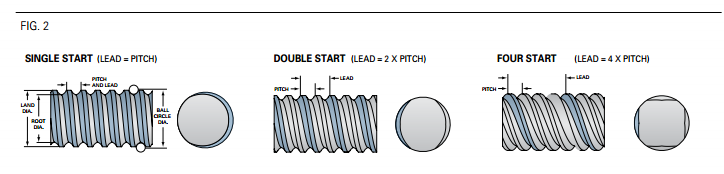

Pitch is the axial distance between two consecutive threads on a screw. Lead is the linear distance traveled by the nut or screw when either is rotated during one full rotation. The starts are the number of independent threads on the screw shaft. There are typically one, two or four starts on a screw, which resemble a helix that wraps around the shaft. The pitch multiplied by the number of starts equals the lead of the screw.

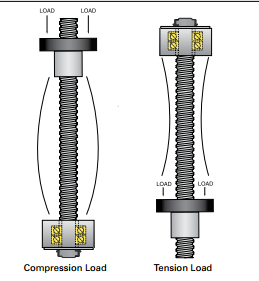

Lash is the result of the axial movement between a nut and screw without rotation. While lash can disrupt the accuracy of the screw, it is typically an occurrence that comes without any serious issues. Normal screws come with a relative amount of lash, and screws which are only loaded in one direction won’t be affected by lash. Lash can be controlled through processes called preloading.

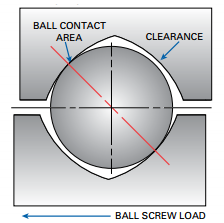

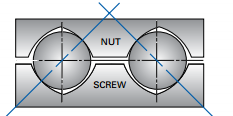

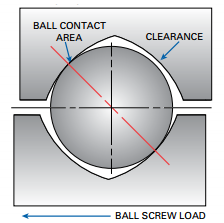

Preloading is the result of an internal force introduced between a ball nut and screw assembly that eliminates free axial and radial lash. There are three methods used for preloading. The double nut method uses two ball nuts that are loaded in opposing directions by a spacer, so that they don’t wiggle when stationary. Lead shifting is a method where a shift or offset is manufactured in the lead of the ball nut. For example, a lead might be shifted from 5 millimeters to 5.05 millimeters in order to shift the ball bearings inside the ball nut in a different direction. This is the preferred method when considering compactness, but load capacity will be reduced. Ball selection is a low-cost method that involves using oversized ball bearings to create four points of contact between the nut and screw. This allows for a heavier load, but the friction from the contact can reduce the life of the bearings.

![PrecisionBallScrewAssembly[1]](http://www.makingmotionwork.com/wp-content/uploads/2015/07/PrecisionBallScrewAssembly1.png)

Some customers have made their own ball screw supports, usually paired on either side of the ball nut in pairs of 2, 4 or 6, to reduce the unsupported distance, essentially quadrupling the critical speed for each pair used. Depending on the application, they can even allow you to select a smaller diameter ball screw, without compromising performance.

Some customers have made their own ball screw supports, usually paired on either side of the ball nut in pairs of 2, 4 or 6, to reduce the unsupported distance, essentially quadrupling the critical speed for each pair used. Depending on the application, they can even allow you to select a smaller diameter ball screw, without compromising performance.