When working with ball screw systems, lashing can sometimes compromise the accuracy of the screw. Lash is the result of the axial movement between a nut and screw without rotation. While lash is not always a bad thing in an application, it can be controlled through preloading or the use of anti-backlash jacks.

Anti-backlash machine screw jacks may be used wherever reversible load conditions require precision positioning control. Leading adjustable backlash machine screw jack models are available to reduce backlash to approximately 0.003 inches.

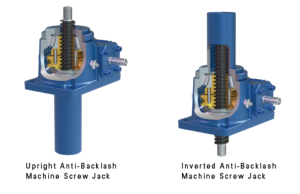

There are number of advantages for using anti-backlash jacks in your applications. An anti-backlash machine screw jack allows the lash between the drive sleeve thread and the lifting screw thread to be controlled by adjusting the top cover of the jack. The anti-backlash jack design has an upper drive sleeve and a lower drive sleeve.

Adjustment of the cover changes the relative distance between the drive sleeves. This change in distance compensates for any lash. Because the drive sleeve is split, the life of an anti-backlash machine screw jack will be less.

Anti-backlash machine screw jacks minimize backlash, but should not be used to completely eliminate backlash. While it may be desirable to totally eliminate backlash, the result would be a lock-up of lifting shaft and drive sleeve.